As communication and information are increasingly moving to a digital format, and certain marketing experts are chanting “print is dead,” one business machine company is poised to capitalize on what could be the next big explosion in print, manufacturing and even the lives of ordinary consumers: 3D printing.

NovaCopy has rapidly grown its office copier sales, support and service business from the ground up; the company was founded in 1998, and has since grown by leaps and bounds into a multimillion dollar operation serving more than 15,000 business clients (grossing nearly $50 million in 2013, and once again making the inc.com Fastest Growing Companies in Tennessee list).

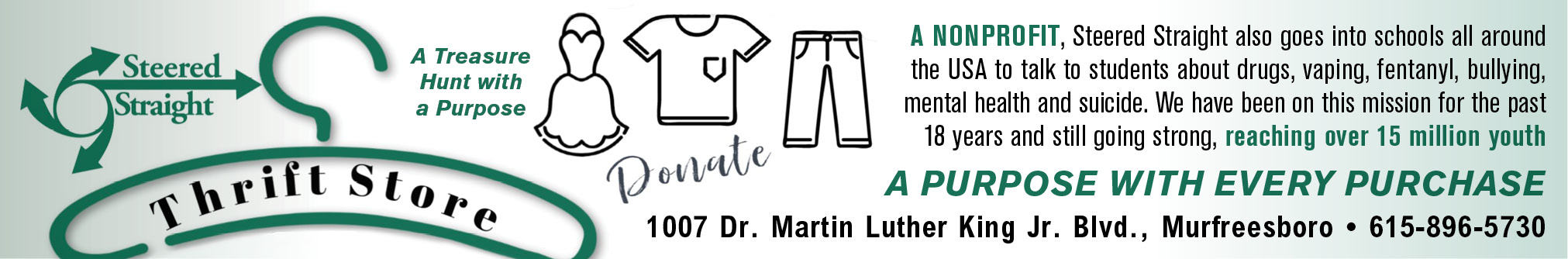

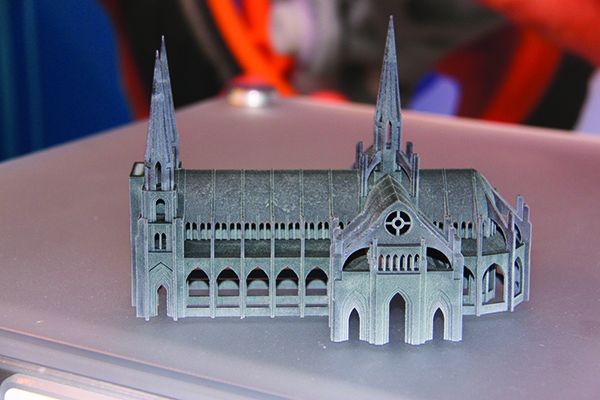

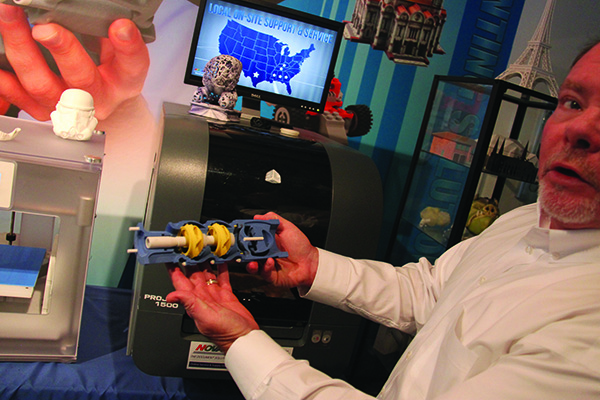

Ever forward-looking, 3D printing is now here for NovaCopy, according to 3D Solutions Specialist Charlie Metz as he shows off just a few of the various items a 3D printer can produce.

These creations can range from a prototype of an athletic shoe and a model of a human fetus in the womb to a building an architect is designing or a prosthetic foot for a duck.

“We are seeing design engineers come up with some pretty cool items,” Metz said. “Doctors can create models of patients. We’ve printed out a heart model.

“But the real application today is all about prototyping,” he said.

If a manufacturer has an idea for a new product, he can let NovaCopy print it “before you spend a million dollars retooling your factory,” Metz said. “This is how 3D printing can help manufacturers bring their products to market faster.”

Converse is one such manufacturer that has utilized 3D printing technology in its prototyping process.

In the past, when conceptualizing and designing a new shoe, the company would send design plans from its designers in the U.S. to its manufacturing facility in Asia. The design process, involving retooling and overseas travel, would take months.

“It was ridiculous,” said Converse Manager for Digital Product Creation Bryan Cioffi.

Today, 3D printing allows the company to print five shoe prototypes in 10 hours, and has saved it hundreds of thousands of dollars in travel and tooling costs, he said.

These shoes aren’t for putting on your feet and wearing, they are prototypes made of plastic, but 3D printers can also “create some end-use products,” Metz said.

One user printed out some decorative shower curtain rings.

“You can put your head on an action figure,” Metz said from the company’s Nashville office.

Often, a type of durable plastic similar to the material Lego uses for its famous building blocks is the medium used by 3D printers. But they can create using a variety of plastics, metals, porcelain, even food.

“Our manufacturer has one called the Chef Jet,” Metz said. These machines can take food, such as chocolate, and print it out in a particular 3D shape. “Our manufacturer, 3D Systems, has a partnership with Hershey,” Metz said.

NovaCopy received international attention in 2013 when it successfully printed a prototype of a duck foot for a disabled duck named Buttercup.

This experiment in engineering and medical technology shows that 3D printing is for far more than printing toys and models; it can make a huge quality of life difference in animals, and by extension, people.

Medical, automotive, aerospace and bioengineering operations are now using these machines, which extract and apply its plastic line by line, similar to the way a desktop printer applies ink to a page line by line, pixel by pixel. But the Cube, made by 3D Systems, and other 3D machines build in three dimensions, from the bottom up, one level at a time.

As with any product “you get what you pay for,” Metz said.

For $1,299, any individual or business can have a personal Cube printer of their own, which prints at a resolution of 200–300 microns (.2–.3 millimeters).

The higher-dollar machines are more precise than the Cube, and can use more colors and materials. Some, which sell for over $100,000, print at a microscopically-detailed resolution of 16 microns (.016 millimeters), Metz said.

If a business is not ready to purchase a 3D machine of their own, NovaCopy offers in-house prototyping services.

“We’ll look at your file for free,” Metz said.

A designer can send over an .stl file (the CAD crew should know the term), and can pick up the object they desire within days or even hours.

“How far away are we from going into a store and getting a custom-printed shoe insole?” Metz said.

“The limitations aren’t necessarily cost, but speed,” he continued, noting even simple jobs on sophisticated machines can now take hours to print.

But if the technology can continue to develop, soon consumers may be able to print out a gear for an automobile transmission or a lens cap for a camera from the local 3D printing center, or even from the comfort of their own home.

If you are interested in learning more about 3D printing, view some of the machines and 3D items at NovaCopy’s downtown Nashville showroom, 15 Lindsley Ave., call Metz at (615) 775-8342 or visit novacopy.com.

Additionally, NovaCopy will soon host 3D printing workshops, covering the basics of 3D printing and items that can be printed. Attendees of this entry-level workshop will experience the 3D printing process through hands-on experience and will learn the intricacies of 3D printing software. For more information on the class, e-mail novacopyusa@novacopy.com.